Bringing parts into a new era of growth

Many organizations create deadlines to keep projects on track. On a farm, the deadlines are imposed by science and nature. Typical planting and harvesting windows span about three weeks each. If a machine goes down during that period, the whole operation can run behind.

We put Farmers First by helping them avoid unplanned downtime so they can maximize productivity and yields. That means having the right part in the right place at the right time — every time. This is essential to serve farmers, and it is a cornerstone of AGCO’s strategy for long-term, sustainable growth.

AGCO’s global parts business unit continues to deliver the highest margins to our business and the dealers and distributors we serve. Even during challenging market conditions, the segment achieved year-over-year growth in 2024. Momentum is on our side, and we are seizing it; we aim to grow the segment from $1.8 billion today to $2.3 billion by 2029. Here’s how we’re making an already thriving part of our business even better.

Increasing availability, expanding sustainable options and improving logistics

The foundation of a successful parts business is a strong fill rate — or the ability to immediately fill orders from our existing inventory. We zeroed in on this capability several years ago and emerged with industry-leading rates in North America and Europe. We have made significant progress toward achieving a similar leadership position in South America, with fill rates in all four regions the segment served at peak levels in 2024.

We don’t rest on our successes — we build on them. In 2024, we invested more than $10 million in expanding remanufacturing (Reman) capacity, which will come online next year, and the business grew by >13% year over year as farms sought alternative, lower-cost alternatives. Reman not only reduces costs and downtime for farmers, but it is also great for sustainability as we reuse material. We also unveiled plans to build a new €87 million (over US$91 million) Parts Distribution Center in Amnéville, France. The facility will be state of the art, complete with solar panels, a rainwater reclamation system, and other sustainable and reduced-carbon features.

Inside, the center will serve as the heartbeat of operations, leveraging leading-edge technologies to boost order fulfillment. It will primarily serve our European and Middle Eastern regions while acting as a “master depot,” supplying parts from Europe to North and South America and the Asia Pacific.

Emblematic of our streamlined business approach, the center will consolidate five facilities into one operation supporting all AGCO brands. It also will provide 24/7 e-commerce parts ordering for dealers and farmers, delivering a more connected, convenient experience.

Growing digital capabilities and e-commerce sales

Despite being an industry where every moment matters, most farmers must stop work and drive to a store to access essential services and parts. We aim to give farmers more control over fleet maintenance and more productive time back in the day.

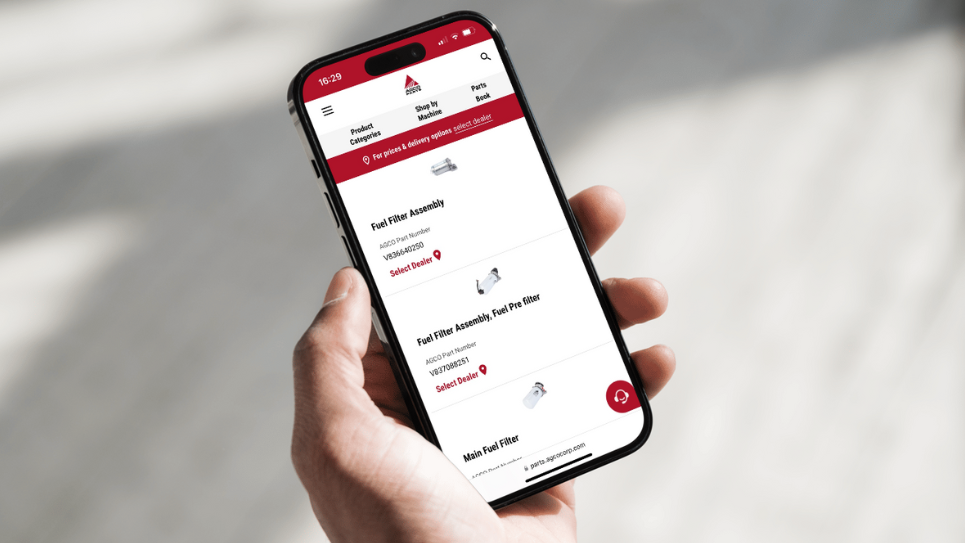

This is possible through strong collaboration with our global dealer network. While dealership locations continue to anchor farmer support in many local communities, mobile and digital channels allow farmers to engage on their terms. Farmers can view digital parts books to see who has a part in inventory and either purchase it at the store or order it online, skipping unnecessary trips to town. As more farmers buy parts through digital channels, AGCO’s e-commerce sales continue to grow. Farmers are seeing the benefits too.

For our dealer network, we also made their work simpler by deploying a business-to-business order fulfillment solution in Europe. Early dealer feedback included: “Simple tool, much better and easier to use than other suppliers” and “What a game changer this tool is, with great features like Supersession and Track and Trace.” In addition, we deployed the AGCO Chatbot to respond to dealer order and pricing queries, with over 30% of answers being received in seconds or minutes vs. hours. Both solutions, which make it easier for dealers to reduce customers’ downtime, will roll out to additional markets in 2025.

Farmers know that we don’t stop thinking about their needs once they’ve purchased a new machine or component; instead, we remain committed to proactively supporting them in their full equipment life cycle needs. We will continue to focus on best-in-class parts availability, total cost of ownership, and digital-enabled solutions to drive customer loyalty and fuel the segment’s steady, high-margin growth.